Mounting the Specimen after cutting is often necessary for subsequent handling and metallographic polishing

When sample requirements include uniform size and shape, and short processing times, hot mounting is ideal

Benefits of Hot Mounting :

Uniform flatness for Grinding & Polishing

Easy Handling of too small specimen

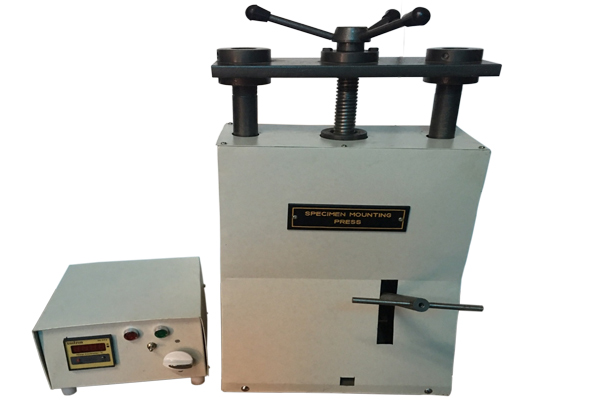

Hot mounting takes place under pressure in a mounting press, where the specimen is placed in a cylinder together with the appropriate mounting resin. A temperature of up to 200°C, and a pressure of up to 50kN are then applied during the embedding of the specimen. There are two types of hot mounting processes: thermoplastic resins and thermo-setting resins.